研究背景

气固两相乃至多相流动广泛存在于过程工程的各个领域(如:石油、化工、冶金、热能和矿业加工等)。这些领域的反应器的设计、放大、控制和优化需要深入理解反应器内的多相流体力学、传递及反应行为,及其与各种复杂流动结构的相互作用,各种控制机制的协调规律等。

研究目标

计算流体力学(CFD)已成功应用于单相流动的模拟,但两相及多相流动由于其内在流动结构的复杂性(非线性、非平衡、多尺度等),模拟方法还远未成熟。传统的双流体模型忽视了非均匀结构对传递的影响,在计算气固相间传递系数时(如:曳力系数、传质/热系数等),将微元内的结构视为可由平均参数表征的拟均匀状态,没有考虑非均匀、介尺度结构(如颗粒聚团、气泡)这一无处不在的两相流本征属性,以及它对动量、质量和热量传递性能的巨大影响。其后果是,计算出的传递系数不准确,在此基础上对反应器的非均匀分布、稳定性、流域变化及反应行为的预测偏差较大,而据此形成的反应器设计和放大不可靠。

本研究的目标将多尺度方法与CFD相结合,发展气固两相流动的多尺度CFD,特别是,将过程所自主提出并发展的EMM模型与CFD结合,形成基于EMSM的稳定性条件约束下的结构多流体方法。该方法从介尺度结构出发,直接对不同结构建立严格的守恒方程,而结构参数的封闭是通过寻找结构的多种控制机制及其协调得到。该方法以及最初的EMMS模型已经形成了一个EMMS注册软件,并授权国内外多家知名研究机构使用(如,Zhou et al., Chem. Eng. J. 2011, 166:306-314; Benyahia, AIChE J. 2012, 58: 427-439)。此外,该方法也在预测流域转变以及诸多工业应用中得到检验。

应用举例

1. 稳定性条件约束的结构多流体模型

图1 稳定性条件约束的结构多流体模型框架(Hong et al., 2012)

2. 流域转变与广义流态化

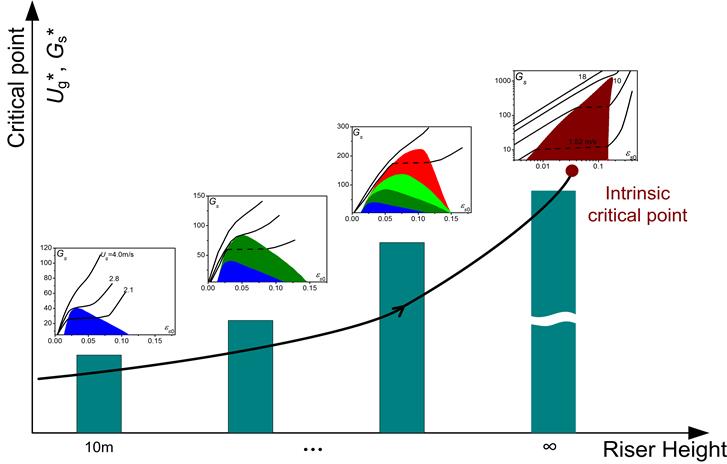

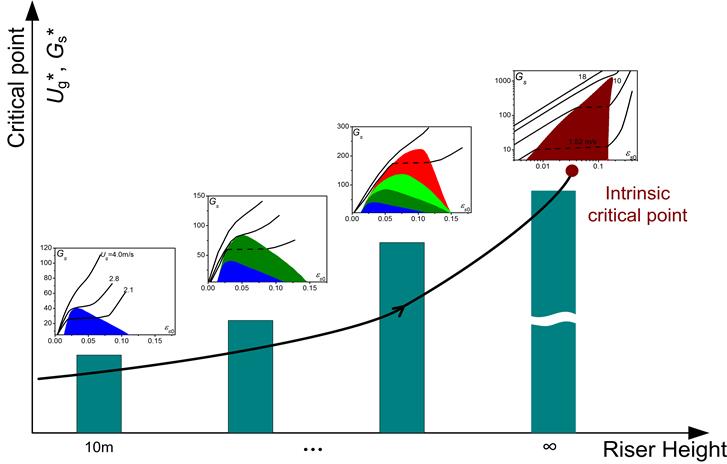

图2 多尺度CFD模拟预测的流域转变图及其随循环床高度的变化:从表观相图到本征相图(Wang et al., 2010)

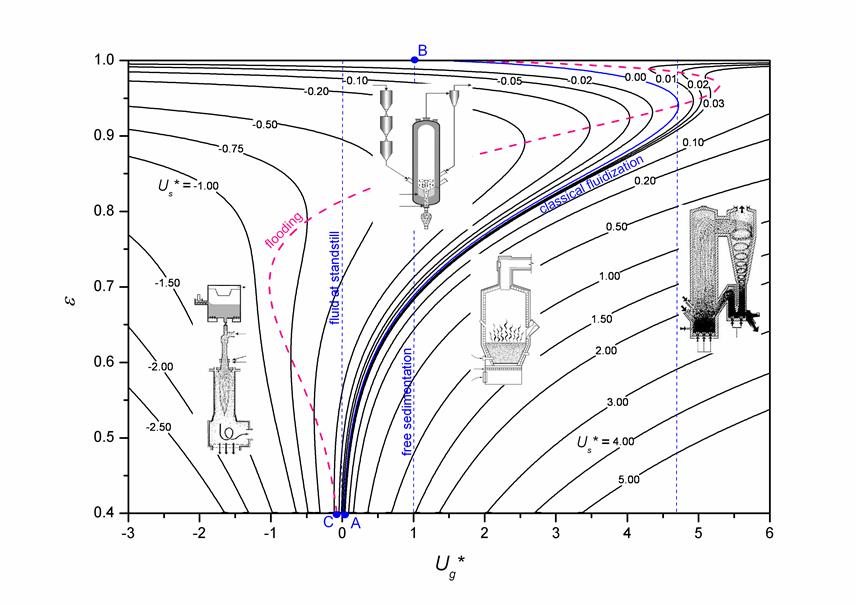

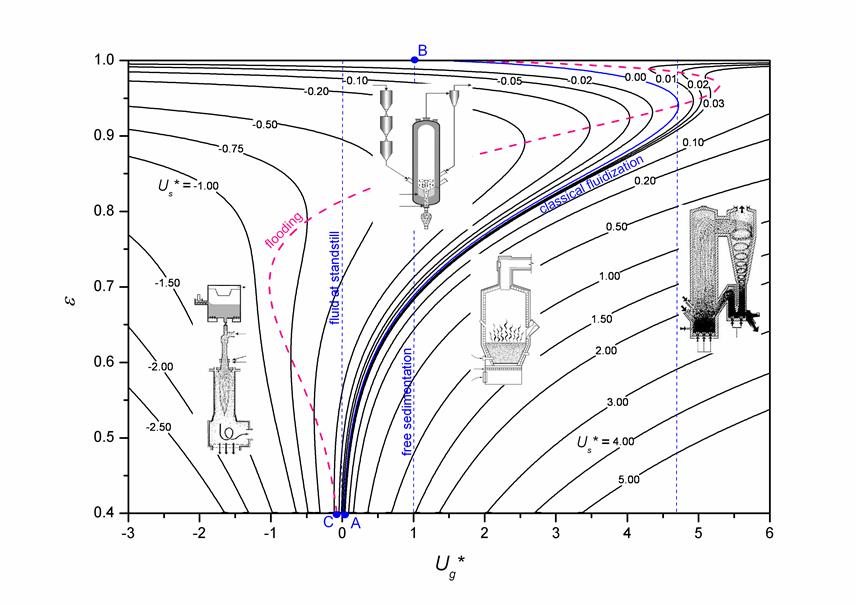

图3 基于考虑介尺度结构影响的力平衡关系,推导出与实际过程吻合的广义流化相图 (Ullah et al., 2013)

3. 多尺度传质

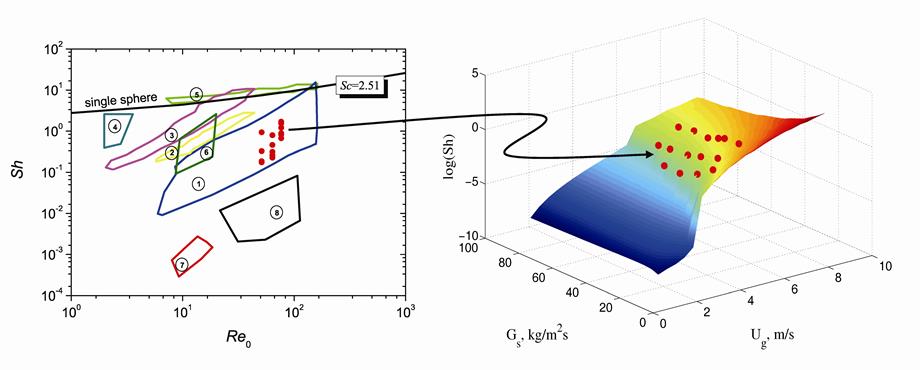

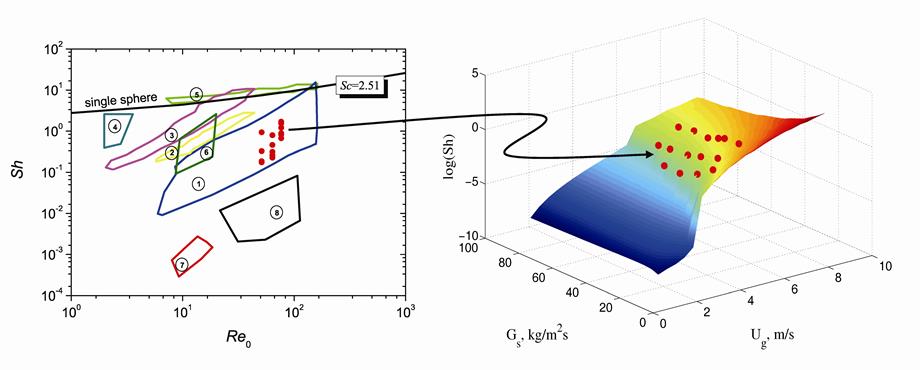

图4 EMMS/mass传质模型解释平均化传质方法造成的数据差异 (Dong et al., 2008)

左:传统方法关联传质系数;右:EMMS方法关联传质系数

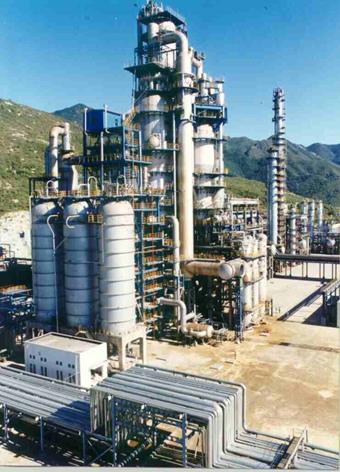

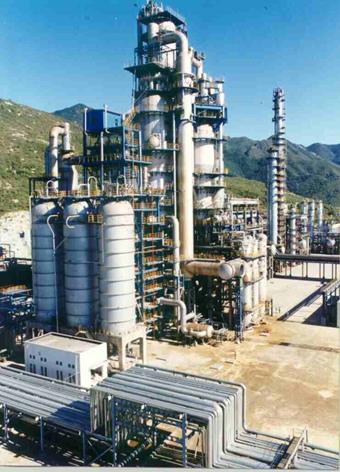

4. 流化催化裂化

图5 多尺度CFD模拟新型催化裂化装置,辅助设计优化、揭示噎塞区域 (Lu et al., 2007)

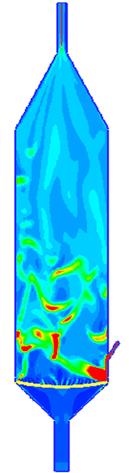

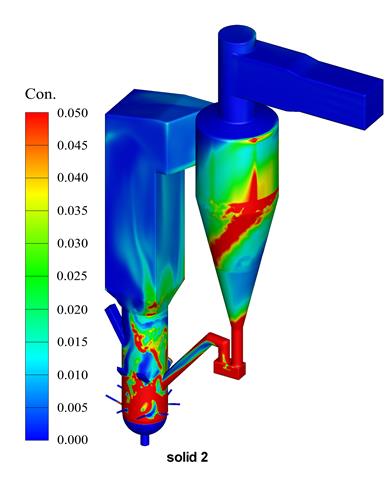

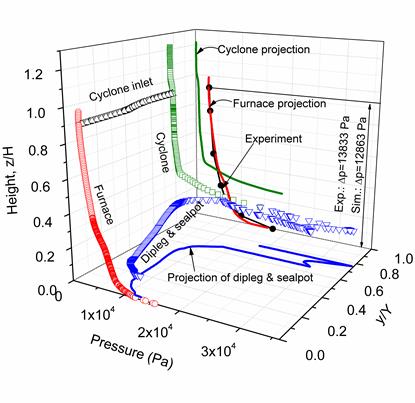

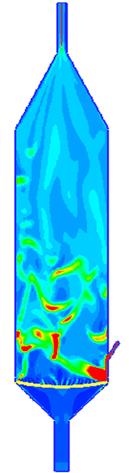

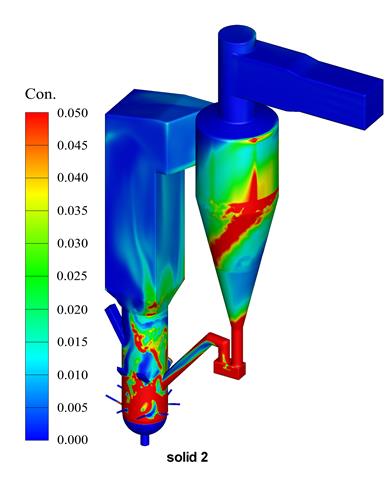

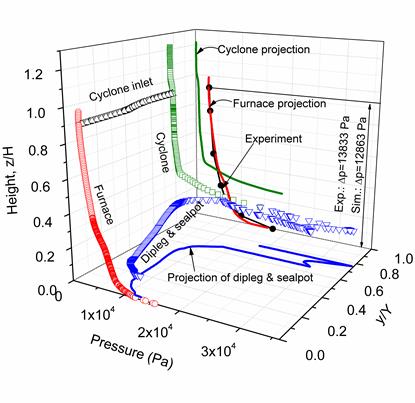

5. 流化床燃烧

图6 多尺度CFD模拟Alstom热态锅炉 (Lu et al., 2013)

左:瞬态浓度分布;右:全床压力分布

代表性论文

- Ullah, A., Wang, W., Li, J. “Generalized fluidization” revisited. Industrial & Engineering Chemistry Research, 2013 (doi: 10.1021/ie3034653).

- Lu, B., Zhang, N., Wang, W., Li, J., Chiu, J., Kang, S. 3D full-loop simulation of an industrial-scale circulating fluidized bed boiler. AIChE Journal. 2013, doi:10.1002/aic.13917.

- Hong, K., Wang, W., Zhou, Q., Wang, J., Li, J. An EMMS-based multi-fluid model (EFM) for heterogeneous gas–solid riser flows: Part I. Formulation of structure-dependent conservation equations. Chemical Engineering Science, 2012, 75: 376-389.

- Wang, W., Ge, W., Yang, N., Li, J. “Advances in Chemical Engineering”, Chapter 1 - “Meso-scale modeling—the key to multiscale CFD simulation” (Ed. G. B. Marin), New York: Elsevier (2011) Vol. 40, pp. 1-58.

- Shi, Z., Wang, W., Li, J. A bubble-based EMMS model for gas-solid bubbling fluidization. Chemical Engineering Science, 2011, 66: 5541-5555.

- Wang, W., Li, J. “Handbook of Combustion”, Chapter 12 - “Modeling of Fluidized Bed Combustion” (Eds. Maximilian Lackner, Franz Winter, and Avinash K. Agarwal), Berlin: Wiley-VCH (2010) Vol. 4, pp. 437-472.

- Wang, W., Lu, B., Zhang, N., Shi, Z., Li, J. A review of multiscale CFD for gas-solid CFB modeling. International Journal of Multiphase Flow. 2010, 36: 109-118. (Ranked one of 100 most influential scientific articles by Chinese scientists, ISTIC, China, in 2011)

- Lu, B., Wang, W., Li, J. Searching for a mesh-independent subgrid model for CFD simulation of gas solid riser flows. Chemical Engineering Science, 2009, 64: 3437-3447.

- Dong, W., Wang, W., Li, J. A multiscale mass transfer model for gas-solid riser flows: part 1- sub-grid model and simple tests. Chemical Engineering Science. 2008, 63: 2798-2810.

- Dong, W., Wang, W., Li, J. A multiscale mass transfer model for gas-solid riser flows: part 2-sub-grid simulation of ozone decomposition. Chemical Engineering Science. 2008, 63: 2811-2823.

- Zhang, N., Lu, B., Wang, W., Li, J. Virtual experimentation thorugh 3-D full-loop CFD simulation of a CFB. Particuology. 2008, 6: 529-539. (Ranked one of most cited Particuology articles since 2007 by Elsevier)

- Wang, W., Li, J. Simulation of gas-solid two-phase flow by a multi-scale CFD approach - extension of the EMMS model to the sub-grid level. Chemical Engineering Science. 2007, 62:208-231. (Ranked one of most cited Chem Eng Sci articles since 2007 by Elsevier)

- Wang, W., Lu, B., Li, J. Choking and flow regime transitions: simulation by a multi-scale CFD approach. Chemical Engineering Science. 2007, 62: 814-819.

- Lu, B., Wang, W., Li, J. et al. Multiscale CFD simulation of gas-solid flow in MIP reactors with a structure-dependent drag model. Chemical Engineering Science, 2007, 62: 5487-5494.

- Yang N, Wang W, Ge W, Li J. CFD Simulation of Concurrent-up Gas-Solid Flow in Circulating fluidized beds with Structure-dependent Drag Coefficient. Chemical Engineering Journal, 2003, 96: 71-80.

联系人: 王维