| 序号 | 文章标题 | 期刊名称 | DOI |

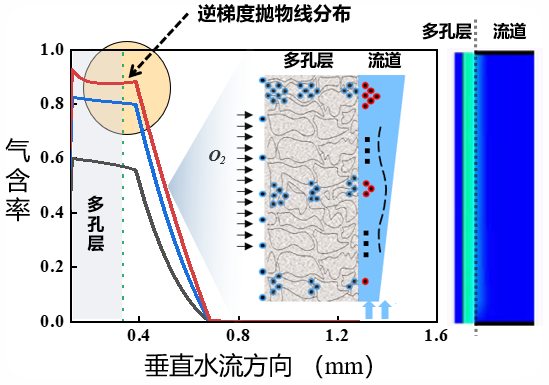

| 1 | Proton exchange membrane water electrolysis at high current densities: Response time and gas‐water distribution | AICHE Journal | https://doi.org/10.1002/aic.18223 |

| 2 | Characterizing bubble behavior in a pseudo-2D fluidized bed of wet particles | AICHE Journal | https://doi.org/10.1002/aic.18207 |

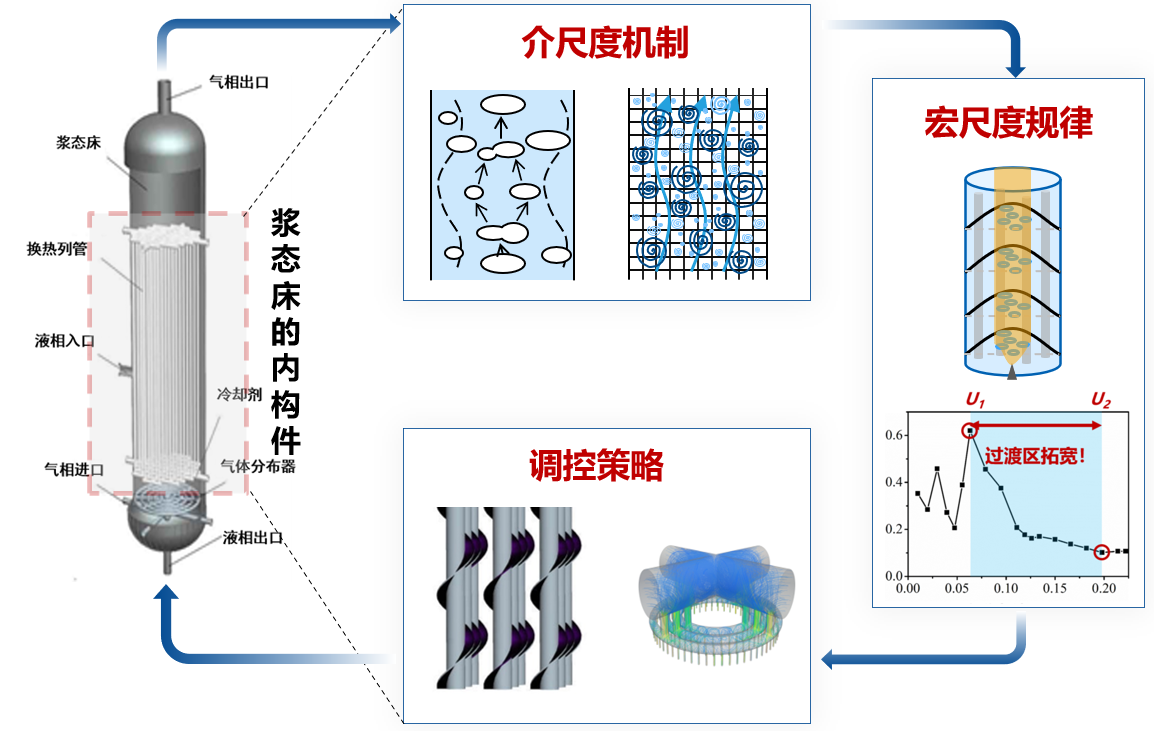

| 3 | Optimization of Slurry Loop Reactors by Understanding the Complex Mesoscale Structure of Liquid–Solid Flow | ACS Engineering AU | https://doi.org/10.1021/acsengineeringau.1c00032 |

| 4 | CFD–DEM simulations of wet particles fluidization with a new evolution model for liquid bridge | AICHE Journal | https://doi.org/10.1002/aic.17681 |

| 5 | Modeling and Optimization of Flow Distribution in Multistage Pipe Distributors | AICHE Journal | https://doi/10.1002/aic.17462 |

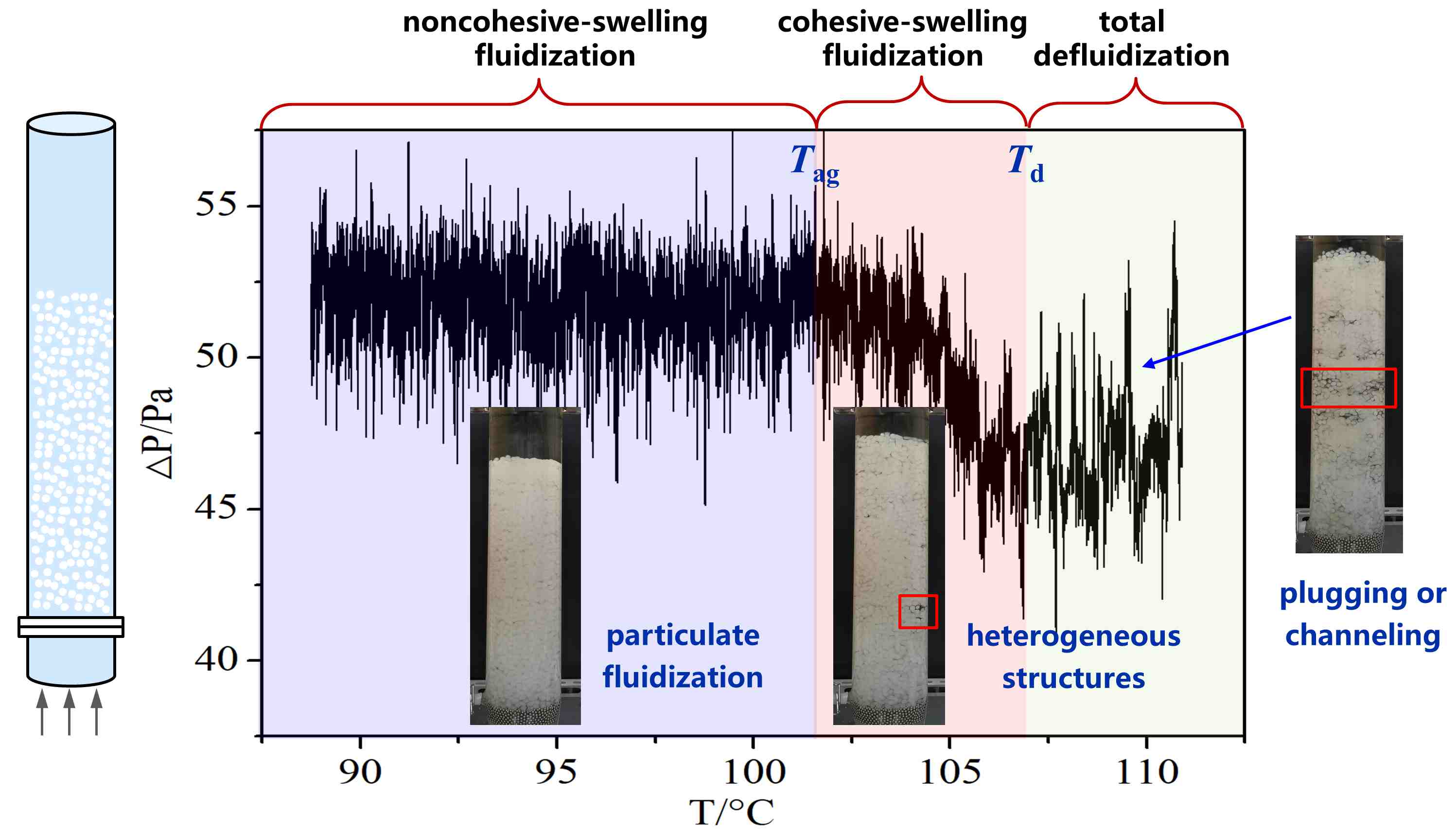

| 6 | Fluidization of Swelling Particles at Elevated Temperatures | Ind. Eng. Chem. Res | https://doi/10.1021/acs.iecr.3c00304 |

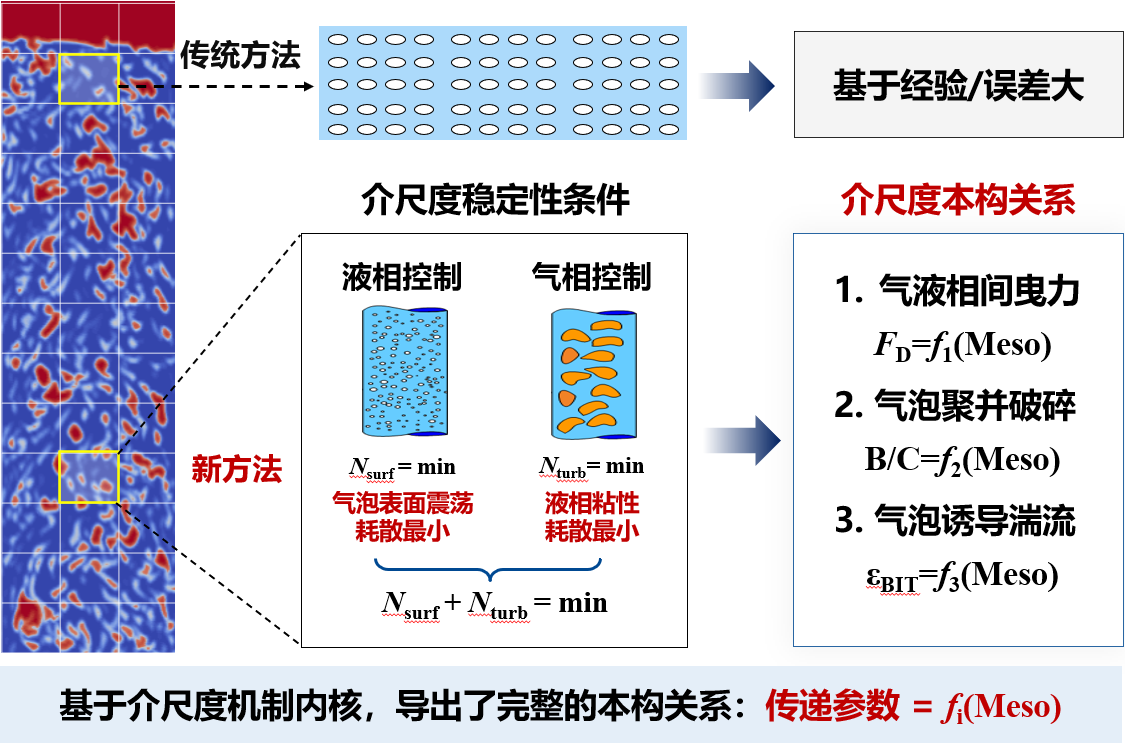

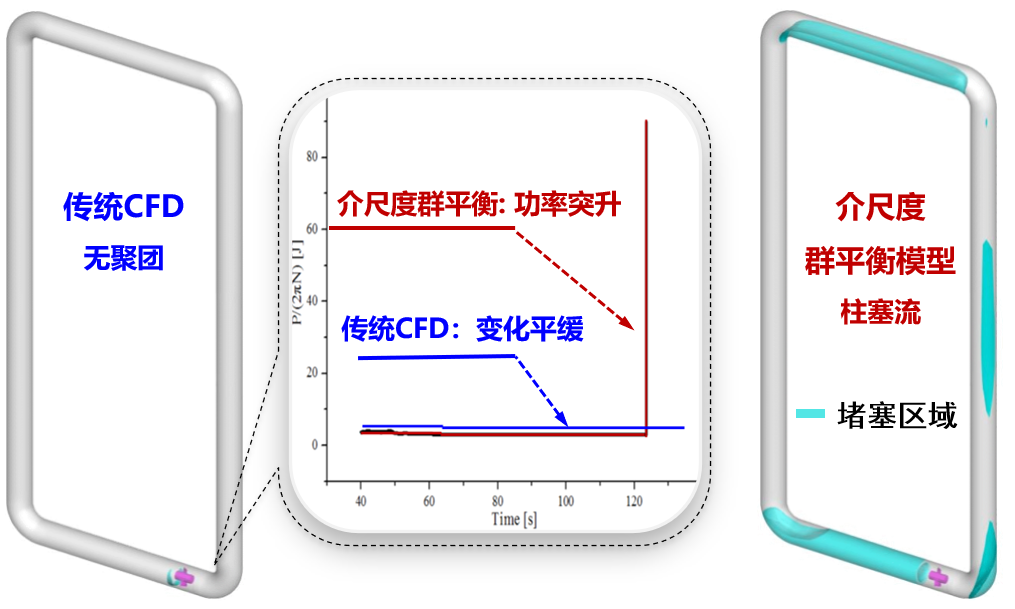

| 7 | 基于介尺度稳定性条件的多相流曳力与群体平衡模型 | 化工学报 | https://hgxb.cip.com.cn/CN/10.11949/0438-1157.20220450 |

| 8 | 内置涡流发生器的管内过冷沸腾与强化换热的模拟 | 过程工程学报 | https://www.jproeng.com/CN/10.12034/j.issn.1009-606X.218281 |

| 9 | 大型反应器内管式气体分布器的研究进展 | 煤炭学报 | http://www.chinacaj.net/d/file/48-2020-S2/951fd4ad6a0c98c74f667d644f6fdfda.pdf |

| 10 | 洗涤冷却室气液两相流的模拟及结构优化 | 过程工程学报 | https://www.jproeng.com/CN/abstract/abstract3768.shtml |

| 11 | 搅拌槽中酯化反应热失控的CFD模拟 | 过程工程学报 | https://www.jproeng.com/CN/10.12034/j.issn.1009-606X.221317 |

| 12 | CO2微气泡强化纳米碳酸钙的制备及传递-反应分析 | 过程工程学报 | https://www.jproeng.com/CN/10.12034/j.issn.1009-606X.222450 |

| 13 | Bubble Size Distribution in a Bubble Column with Vertical Tube Internals: Experiments and CFD‐PBM Simulations | AICHE Journal | https://doi.org/10.1002/aic.17755 |

| 14 | Bubble-induced turbulence in CFD simulation of bubble columns. Part I: Coupling of SIT and BIT | Chem. Eng. Sci | https://doi.org/10.1016/j.ces.2023.118528 |

| 15 | A new drag model for CFD modeling of bubble columns with surfactant | Chem. Eng. Journal | https://doi.org/10.1016/j.cej.2022.140682 |

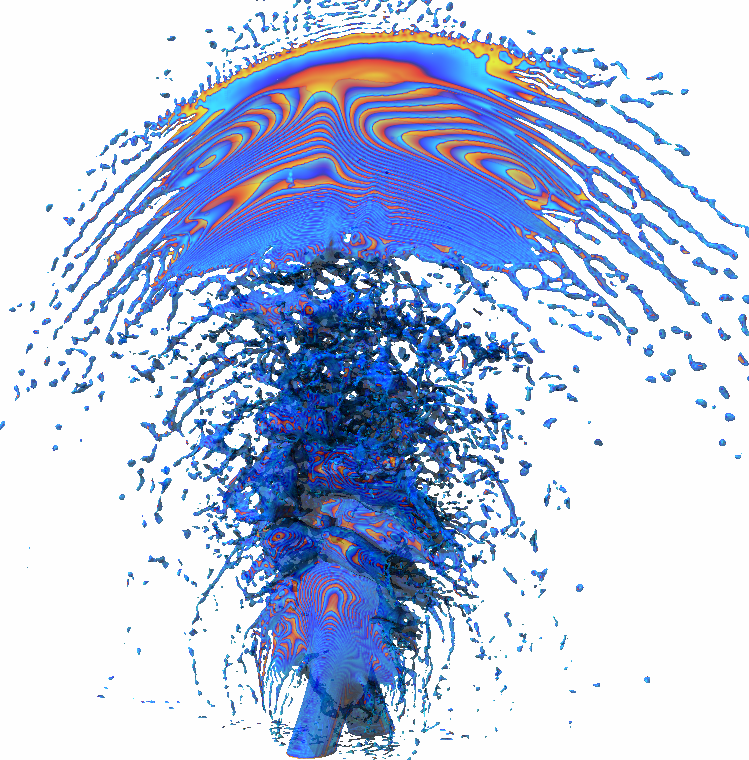

| 16 | Modeling Partition Coefficient of Liquid Droplets Impacting on Particles by Direct Numerical Simulation | Chem. Eng. Sci | https://doi.org/10.1016/j.ces.2022.117553 |

| 17 | Lattice Boltzmann Simulation of Drop Splitting in a Fractal Tree-Like Microchannel | Chem. Eng. Sci | https://doi.org/10.1016/j.ces.2021.117277 |

| 18 | Hydrodynamics in Bubble Columns with Helically-Finned Tube Internals: Experiments and CFD-PBM Simulation | Chem. Eng. Sci | https://doi.org/10.1016/j.ces.2021.116674 |

| 19 | Characterizing Regime Transitions in a Bubble Column with Internals | AIChE Journal | https://doi.org/10.1002/aic.17167 |

| 20 | Modeling the Effects of Solid Particles in CFD-PBM Simulation of Slurry Bubble Columns | Chem. Eng. Sci | https://doi.org/10.1016/j.ces.2020.115743 |

| 21 | Effects of liquid property on onset velocity of circulating fluidization in liquid-solid systems: A CFD-DEM simulation | Powder Technology | https://doi.org/10.1016/j.powtec.2020.01.051 |

| 22 | Characterizing Regime Transitions in a Bubble Column with Internals | AICHE Journal | https://doi.org/10.1002/aic.17167 |

| 23 | Regime Mapping of Multiple Breakup of Droplets in Shear Flow by Phase-field Lattice Boltzmann Simulation | Chem. Eng. Sci | https://doi.org/10.1016/j.ces.2021.116673 |